Ultrashort femtosecond lasers are known for their capacity to efficiently fabricate complex nanostructures and devices for a wide variety of applications: micro-optical components, gratings, biomedical engineering etc. In two recent studies, on both sides of the Atlantic, in which other characterization methods failed to yield valid results, the properties of femtosecond laser-structured surfaces were revealed thanks to a unique SEM image reconstruction technique.

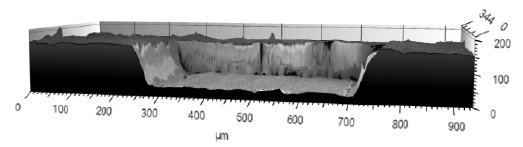

Above. Cavity machined with a femtosecond laser.

Comparing roughness of surfaces

Materials science student Mickaël Le Barh (above) recently completed a study on femtosecond laser micromachining optimization for the Department of Mechanical Engineering at the University of Ottawa (Canada).

“Deep cavities (500 µm x 500 µm x 100 µm) were machined with a femtosecond laser (see image above) and our goal was to get the smoothest surfaces possible on the bottom and sides of the cavities. To achieve this, we adjusted machining parameters using visual quantification but found it was also useful to be able to perform roughness measurements.”

“Initially I attempted to do this using an atomic force microscope (AFM) but the complex geometry of the sample prevented the microscope from accessing the bottom of the cavity. Using a Zeiss scanning electron microscope equipped with Mountains® software, we were able to obtain the desired result.”

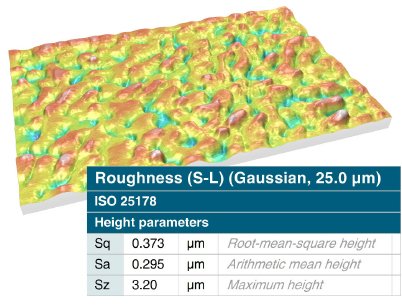

Above. 3D reconstruction of cavity base with roughness parameters.

“Obtaining smooth surfaces using ultrafast lasers is relevant in many applications where slower processes are currently used such as in sample preparation for electron microscopy, fabrication of microfluidic channels, 3D serial sectioning, micro-electro-mechanical systems and micro-optical elements.”

Surface wettability in biomedical applications

In a similar application, Vahan Malkhasyan, PhD Researcher in Laser Material Processing at the FEMTO-ST Institute in Besançon, France has been studying femtosecond laser-matter interaction of metals and transparent materials for fabricating super-hydrophobic (water-repellent) and super-hydrophilic (super-wetting) surfaces for biomedical devices. Once again, 3D reconstruction of SEM images was paramount to getting reliable results.

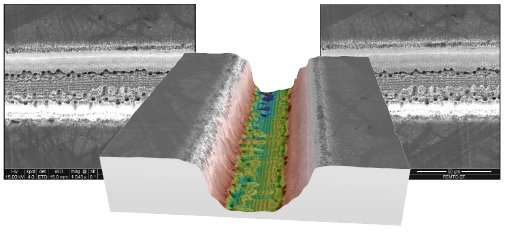

Above. 3D model of a laser ablated micro-line reconstructed from two SEM images obtained at different tilt angles.

“In this study, it was important to measure the depth of crater impacts & lines ablated on different surfaces. The depths to be quantified were situated in the 5-60µm range” explains Vahan. “We compared topographies obtained by stereo reconstruction of SEM images and by optical and mechanical measurements.”

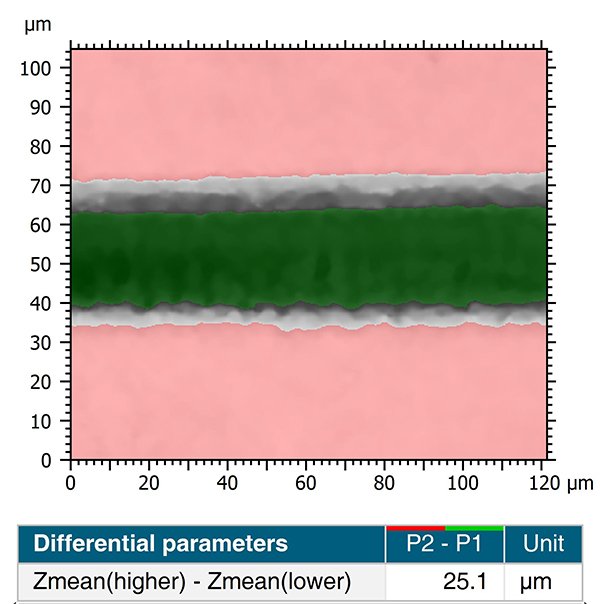

“Using our 3D profilometer, it was difficult to obtain profile depth values of the impacts. In some cases, the values found were inaccurate. However using our FEI SEM to obtain two images of the sample which were then built into a 3D model using Mountains® software gave much more credible values (see image below).”

Above. Automatic step height measurement performed on reconstructed SEM data.

Instruments & software used

Scanning Electron Microscopes (SEM) + MountainsSEM® software