The ISO 13565 series of standards are specially aimed at characterizing stratified surface texture produced by a two-step manufacturing process such as honing-polishing machining.

An automotive manufacturer used Mountains® to study parameters associated with wear and lubrication.

Mountains® tools used

-

Filter measured profile

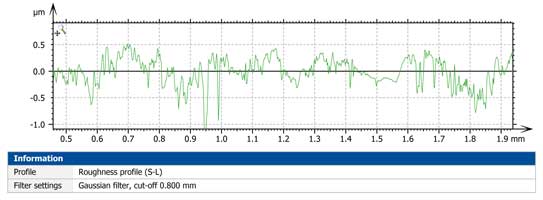

The “Filtered profiles” study was used to display the roughness curve (the raw and waviness profiles can be shown as well).

-

Rk parameters

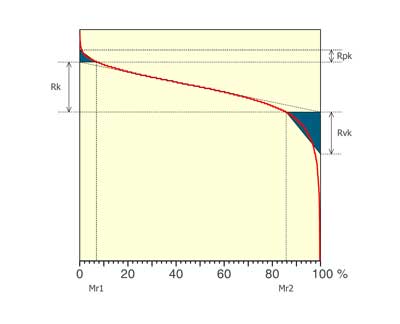

The “Rk parameters” study was used to visualize the way ISO 13565-2 (or DIN 4776) parameters (also called functional parameters or Bearing Ratio parameters) are calculated from the Abbott curve.

The graphical study shows the Abbott-Firestone curve and the following parameters:

| Rk | Kernel roughness (roughness depth of the core) |

| Rpk | Reduced peak height (roughness depth of the peaks) |

| Rvk | Reduced valley depth (roughness of the valleys) |

| MR1 | Upper material ratio |

| MR2 | Lower material ratio |

| A1 | Upper area (area of the upper triangle equivalent to the peaks) |

| A2 | Lower area (area of lower triangle equivalent to the holes) |

Instrument & software used

2D profilometer + MountainsMap® Profile software