Newsletter

Stay up to-date with the latest imaging, analysis and metrology news from Digital Surf.

In the last few years, the use of SPM techniques in many areas of research has greatly increased. Professor Philippe Leclere, director of the LPNE at the University of Mons (UMONS) in Belgium, has been studying the impact of this increase and describes how his team is addressing the challenge of analyzing and mapping large quantities of data on material properties at the nanoscale.

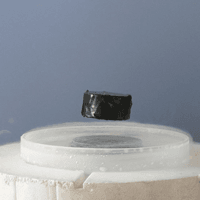

Researchers at the Institut de Ciència de Materials de Barcelona characterizied surface texture of superconductor materials with the aim of improving their performance.

A team at Widener University (Chester, Pennsylvania, USA) recently used bimodal AFM technique and MountainsSPIP® software to study the calcification process of polylactic acid polymer (PLA), a plastic filament material widely used in 3D printing.

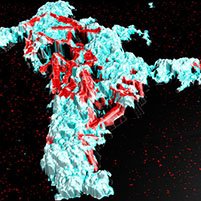

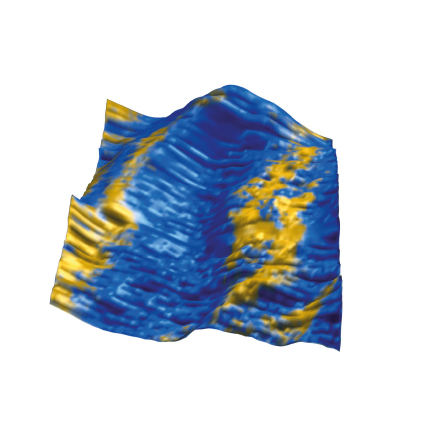

Researchers at the Structural Nanomechanics Lab at Dalhousie University in Canada have been investigating the nanomechanical behavior of Collagen I fibrils. Their study demonstrated that nanomechanical mapping can detect subtle changes in molecular dynamics and fibril architecture. This article explains how Mountains® software allows fine-tuning and detailed analysis of force volume data.

The Institute of Electronics, Microelectronics and Nanotechnology (IEMN) in France recently completed the “Dirac III-V” project investigating ways of producing Dirac electrons (electrons without any mass). This project called for the use of many different fabrication methods as well as a software program capable of bringing together and processing the different kinds of datasets generated.

For this application, a research team at the LNE Nanotech Institute combined measurements from several instrument techniques including Atomic Force Microscopy (AFM) and Scanning Electron Microscope (SEM) equipped with a new-generation energy dispersive X-ray detector (EDX). They used MountainsLab® software to correlate the collected data and extract the relevant information.

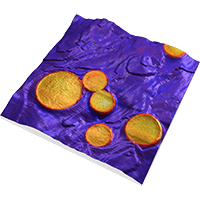

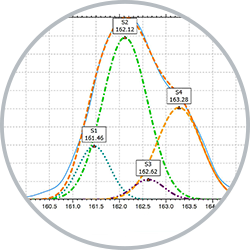

Scientists from the ISEN (Institut Supérieur de l’Électronique et du Numérique) in Lille, France, used photoelectron spectroscopy to investigate a new method for growing PbS nanoplatelets on InP surfaces.

Bruno Grandidier, research scientist with the French National Center for Scientific Research (CNRS), reports on his work, focused on understanding the electronic properties of silicon dangling bonds.

Bioceramics are particularly useful in the repair and reconstruction of bone. A group of researchers at the University of Limoges investigated the impact of bioceramic surface topography and composition on protein adhesion forces.

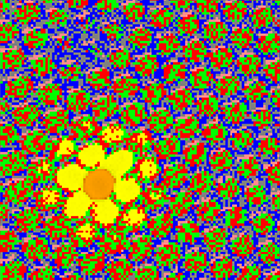

Recently, graphene oxide nanostructures have attracted great interest due to their exceptional physicochemical properties for many applications, including flexible electronics and water purification.

During the last decade, research has shown that bio-oil fermentation by micro-organisms is a promising potential source of bio-fuel. Its renewability makes it a good alternative to bio-fuel production.

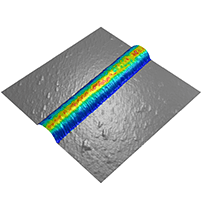

The goal of the NanoRef programme, involving multiple partners (LP-Cnam, INM, LPUB, Institut Fresnel, Novasic and LNE), is to develop a roughness standard with a quasi-continuum spatial frequency spectrum and to define the appropriate machining and polishing processes.