Newsletter

Stay up to-date with the latest imaging, analysis and metrology news from Digital Surf.

The goal of the NanoRef programme, involving multiple partners (LP-Cnam, INM, LPUB, Institut Fresnel, Novasic and LNE), is to develop a roughness standard with a quasi-continuum spatial frequency spectrum and to define the appropriate machining and polishing processes.

LABMEM facility scientists at the Universidad Nacional de San Luis (Argentina) investigated properties of an inorganic compound for use as a solid electrolyte on a high temperature fuel cell (SOFC type).

Researchers at the FEMTO-ST Institute in Besançon, France studied methods for fabricating lithium niobate ridges to be used for the development of programmable microcomponents.

Nanolithography is a precise patterning technology used to fabricate functional nanostructures for applications in biosensors, advanced materials and extensively in the semiconductor sector for solar cells, printed electronics, LED, MEMS, etc.

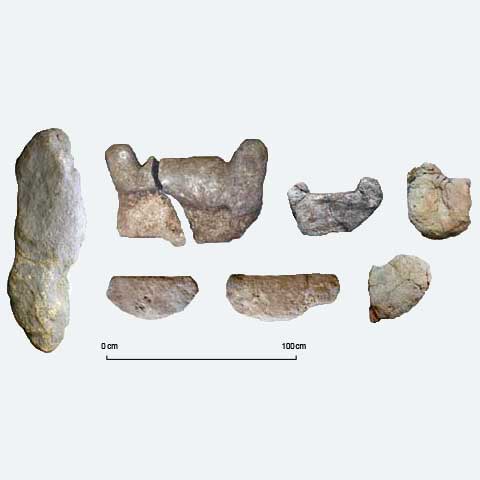

Tools for measuring surface roughness were used to study stelae and a menhir from the Late Neolithic-Chalcolithic period (around 3000 BC) discovered during the excavation of a prehistoric settlement in the Serra del Mas Bonet in Catalonia (Spain).

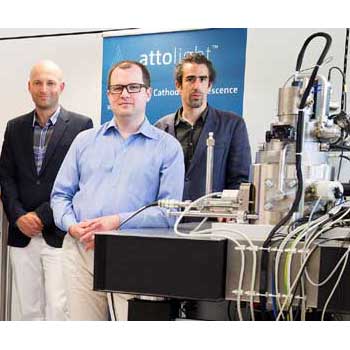

Quantitative cathodoluminescence technology coupled with the power of Mountains® software made it possible to localize and identify degraded layers in state-of-the-art green laser diodes.

Friction, core and lubrication zones of a motor cylinder were studied in order to investigate opportunities for improving fuel efficiency and thus reduce harmful emissions. Mountains® software was used to provide advanced analysis of the volume of the zones studied.

In today’s competitive environment, industrial manufacturers continue to invest heavily in tests aoming to improve metal coating performances. In this case study, scratches on a copper surface with tin deposits were measured by a 3D optical profiler.

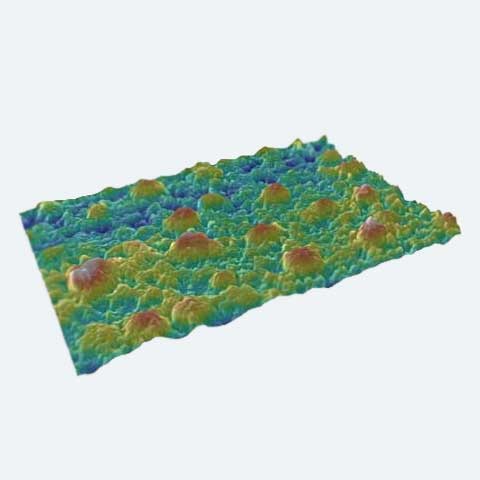

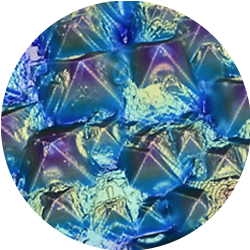

Pyramid-shaped solar cells are particularly effective for converting energy from the sun into usable energy without the problem of overheating. In a study on solar cell performance enhancement, industrial researchers used Mountains® to visualize surface topography in 3D and overlay a color image of solar cells on topography.

The analysis of microwear on archaeological stone tools was used to identify tool function and improve understanding of prehistoric hunter-gatherer behavior